A Practical Guide to Choosing Auto Paint Primers

Share

The Foundation of a Flawless Finish: Why Primer Matters

Automotive primers are the essential first layer in any automotive painting project, creating a strong bond between the substrate and the topcoat. They also protect against corrosion and fill minor surface imperfections, ensuring a durable, long-lasting finish. Without a quality primer, paint can peel, chip, or fail prematurely.

What You Need to Know About Auto Paint Primers

- Epoxy Primer: Best for bare metal, offering maximum corrosion protection and adhesion.

- Urethane Primer: High-build formula that fills scratches and is easy to sand.

- Etch Primer: Self-etching formula for bare metal that creates a strong chemical bond.

- 1K Primers: Single-component, convenient for small jobs, and air-drying.

- 2K Primers: Two-component with a hardener for professional-grade durability.

- High-Build Primers: Thicker consistency for filling dents and surface flaws.

Proper surface preparation with the right primer is non-negotiable for achieving results that last. Whether you are performing a spot repair or a complete restoration, understanding which primer to use is the key to a professional-looking finish.

The Three Core Functions of Automotive Primer

A primer serves three critical functions to ensure a professional and durable finish. Without this solid foundation, even the best topcoat is at risk of failing.

First, primer creates a strong bond between the substrate and the topcoat. It acts as an adhesive layer, locking the paint system together on surfaces like bare metal, plastic, or fibreglass. This combination of a mechanical and chemical bond prevents the basecoat from bubbling, flaking, or peeling.

Second, primer provides a protective barrier against corrosion. This is vital for bare metal, as exposure to air and moisture immediately starts the oxidation process. Primer seals the metal with a non-porous shield, keeping corrosive elements out. Our PPG EPOTEC 2K Primers, for example, are formulated for superior corrosion resistance and long-term protection.

Third, primer fills minor imperfections to create a smooth, uniform surface. Microscopic scratches, pinholes, and texture variations can show through the topcoat if not addressed. Primer levels the surface by filling these flaws, creating a perfect canvas for your colour coat and ensuring an immaculate final appearance.

These three functions work together to make a high-quality paint job possible. Primers are the unsung heroes of any refinishing project.

Primer vs. Surfacer: What's the Difference?

While the terms "primer" and "surfacer" are often used interchangeably, they have distinct roles. Understanding the difference helps you choose the right product and avoid rework.

A primer's main job is adhesion and sealing. As the first coat on a prepared surface, it bonds to the substrate and creates a non-porous layer to protect against corrosion. Products like our EPO 2K Primers excel at this, offering robust adhesion and corrosion resistance over bare metal.

A surfacer, also known as a "filler primer" or "high-build primer," is designed to fill surface imperfections. With a higher solids content, it has a thicker consistency to fill small dents, deep sanding scratches, and pinholes in body filler. Surfacers are applied in thicker coats and sanded to create a perfectly level foundation, making them ideal for surfaces that have had bodywork.

Many modern 2K (two-component) auto paint primers combine both functions, offering excellent adhesion and filling capabilities. However, for significant imperfections, a dedicated high-build surfacer is more efficient. Our expert team at Eastern Auto Paints can help you decide if a primer, surfacer, or combination product is best for your project.

A Comparison of the Main Types of Auto Paint Primers

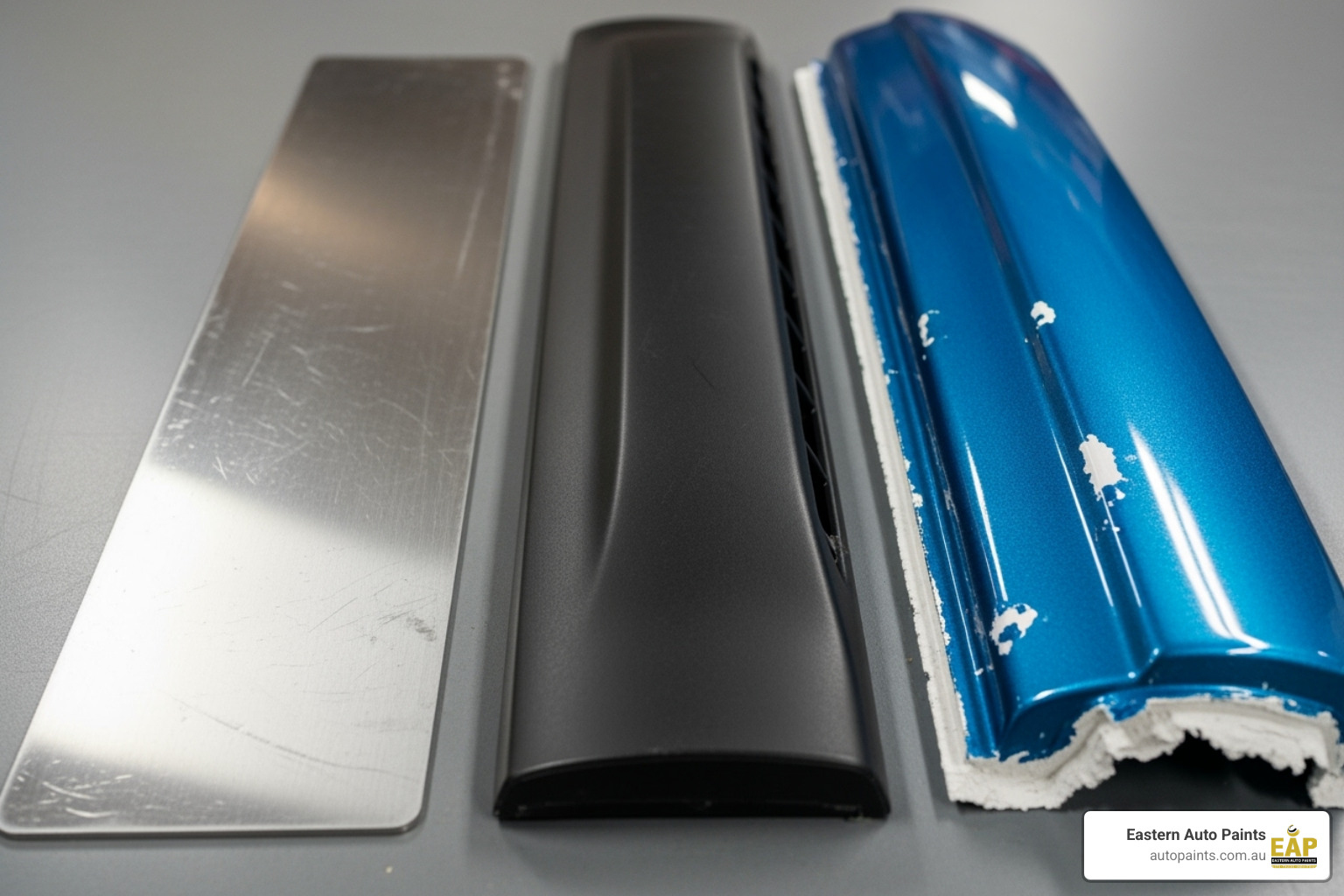

Choosing the right auto paint primer is critical, as different substrates and project goals require different solutions. The three most common types are epoxy, urethane, and etch primers, each with unique properties for achieving a professional, long-lasting finish.

| Criteria | Epoxy Primer | Urethane Primer (Surfacer) | Etch Primer |

|---|---|---|---|

| Best For | Bare metal, rust prevention, sealing | Filling imperfections, general purpose, over old paint | Bare metal adhesion (especially aluminium) |

| Adhesion | Excellent, forms a strong bond | Very good, versatile over various substrates | Excellent, chemically bites into metal |

| Corrosion Resistance | Superior, non-porous barrier | Good, seals surface | Good, but needs a topcoat for full protection |

| Filling Properties | Minimal (primarily a sealer) | Excellent, high-build for filling scratches/pinholes | Minimal (very thin) |

| Sanding | Can be challenging, hard when cured | Easy to sand to a smooth finish | Not typically sanded, often top-coated wet-on-wet |

| Common Substrates | Bare steel, aluminium, fibreglass, body filler | Existing paint, body filler, some plastics | Bare steel, aluminium, stainless steel |

Epoxy Primer: The Ultimate in Durability and Protection

Epoxy primers are two-component (2K) products known for exceptional adhesion and superior corrosion resistance. They create a robust, non-porous barrier that locks out moisture, making them the ideal first coat for restorations or extensive bare metal exposure. While not designed to fill deep imperfections, they provide an incredibly stable foundation for body filler or a high-build surfacer. Our EPO 2K Primers are a best-selling choice for their reliability and performance on projects where maximum durability is essential.

Urethane Primer: The Versatile Filler and Surfacer

Urethane primers are the workhorses of the modern body shop, excelling at filling scratches, pinholes, and other minor flaws. As high-build surfacers, they have a high solid content and are easy to sand to a smooth, uniform finish, saving time and effort. Urethane primers offer good flexibility and adhesion over various surfaces, including existing paint and body filler. Typically 2K products, they are a durable and sandable foundation for general panel repairs. You can find a wide range of these in our primers and fillers collection.

Etch Primer: The Adhesion Expert for Bare Metal

Etch primers are specialised primers designed to create an incredibly strong bond with bare metal. They contain mild acids that chemically "etch" into the metal surface, providing superior adhesion, especially on aluminium and galvanised steel. Because they are very thin and offer minimal filling properties, they must be coated with a compatible urethane or epoxy primer to provide build and corrosion protection. Many etch primers, like our Protec Etch Primers, come in convenient aerosol cans for smaller repairs and are quick-drying.

Understanding Key Primer Formulations

Beyond chemical types, auto paint primers are also categorised by their composition. Understanding the difference between 1K and 2K products, as well as high-build and regular formulas, is crucial for selecting the right product for the job.

1K vs. 2K Primers: A Guide to Auto Paint Primers

The terms 1K and 2K refer to the number of components needed for the primer to cure.

A 1K (one-component) primer is a single-part formula that comes ready to use. It cures through solvent evaporation when exposed to air, making it convenient for small jobs and quick touch-ups. You'll often find them in aerosol cans, like those in our 1K primers range. However, 1K primers offer limited durability and chemical resistance compared to 2K products.

A 2K (two-component) primer requires a hardener or activator to be mixed in before application. This triggers a chemical reaction (cross-linking) that results in a much harder, more durable, and chemically resistant finish. 2K primers are the industry standard for professional repairs and full resprays, offering superior longevity. Our 2K primers are trusted by professionals for this reason. When working with 2K products, always use proper PPE (personal protective equipment) masks, as the hardeners contain isocyanates, which require respiratory protection.

High-Build vs. Regular Primer: A Guide to Auto Paint Primers

The choice between a high-build and a regular primer depends on the surface condition.

A high-build primer has a higher percentage of solids, giving it a thicker consistency. It can fill minor dents, deep sanding scratches, and other surface unevenness in just a few coats, making preparation more efficient. After application, it is sanded to create a perfectly flat, smooth surface for the topcoat.

Regular primers, or primer-sealers, are thinner and are not designed to fill significant imperfections. Their job is to provide a uniform, non-porous layer that promotes adhesion and prevents the topcoat from soaking into the substrate. This is vital for ensuring consistent colour and gloss. They are ideal for surfaces that are already smooth and require less sanding than high-build primers.

Other Less Common Types of Automotive Primers

While epoxy, urethane, and etch primers cover most needs, a few other specialised auto paint primers are useful in specific situations.

Polyester Primer

Polyester primers offer extremely high-build filling power, almost like a sprayable body filler. They are designed to tackle deep scratches and significant imperfections, saving time in the preparation stage. However, they can be brittle if applied too thickly and require careful mixing with a catalyst. They should be applied over an epoxy or etch primer for proper adhesion and corrosion protection, not directly to bare metal.

Enamel Primer

Typically 1K (one-component) products found in aerosol cans, enamel primers provide a good base for enamel topcoats and offer reasonable corrosion resistance. They are an economical option for less demanding applications, such as interior components. However, they lack the durability and versatility of 2K systems and may not be compatible with all modern paints.

How to Choose the Right Primer for Your Project

Choosing the right automotive paint primer is essential for a durable, professional-quality result. Consider these key factors to make an informed decision.

-

Substrate Material: The material you are painting is the most critical factor.

- Bare Steel or Aluminium: Use an etch primer like our Protec Etch Primers or our Ppg Eps - series for initial adhesion or an epoxy primer for superior corrosion resistance.

- Plastic: Requires a specialised plastic adhesion promoter before applying a compatible urethane primer. We stock Protec Plas Stik Primer which is suitable

- Fibreglass: Epoxy primers provide excellent adhesion and sealing.

- Existing Paint: A urethane primer surfacer is suitable if the paint is in good condition and properly scuffed.

- Body Filler: Always seal with a 2K urethane primer surfacer.

-

Surface Condition: Assess how much repair the surface needs.

- Deep Scratches or Unevenness: A high-build urethane primer is ideal for filling imperfections efficiently.

- Smooth and Blemish-Free: A regular primer-sealer will provide adhesion and a uniform base without adding unnecessary thickness.

Paint System Compatibility: Always ensure your primer, basecoat, and clearcoat are compatible. Check the product's technical data sheet (PDS) to prevent adhesion failure or other defects. Our PPG Industrial Paints and Protec Automotive Paint Systems are designed for seamless compatibility.

-

Project Goal: Your goal determines the required durability.

- Quick Spot Repair: A 1K aerosol primer from our primer aerosols range can be convenient.

- Durable Full Respray: A full 2K system, starting with an epoxy or urethane primer, is the professional standard for long-lasting results.

Common Mistakes to Avoid When Applying Primer

Even the best automotive primers can fail if not applied correctly. Avoiding these common mistakes will save you time, money, and frustration.

Improper Surface Preparation: This is the most common cause of paint failure. Always apply primer to a clean, degreased, and properly sanded surface. Skipping this step will lead to peeling, lifting, or bubbling.

Applying Primer Too Thick: Piling on thick coats traps solvents, which can cause slow drying, pinholes, shrinkage, or cracking. Apply primer in multiple, even coats with adequate flash-off time between each.

Ignoring Drying Times: Sanding or top-coating primer before it is fully cured can cause solvent pop, mapping, or poor adhesion. Always follow the recommended drying and recoat times on the product's technical data sheet.

Using the Wrong Primer for the Substrate: As discussed, not all primers are created equal. Using a standard primer on bare aluminium or an etch primer over body filler can lead to failure. Always match the primer to the material.

Inadequate Mixing of 2K Primers: 2K products require precise mixing of the primer and hardener. Incorrect ratios can prevent the primer from curing properly, leaving it soft and vulnerable. Always use measuring cups and follow instructions.

Poor Spray Technique: Inconsistent application leads to an uneven surface that is difficult to sand and will show through the topcoat. Practice on a test panel and use quality equipment like Sata spray guns for consistent results.

Ignoring Temperature and Humidity: Environmental conditions affect how primers cure. Avoid applying primer in extreme cold, heat, or humidity. Aim for moderate temperatures, around 16°C to 35°C (60°F to 95°F), and low humidity.

Frequently Asked Questions about Auto Paint Primers

Here are answers to some of the most common questions we receive about auto paint primers.

Can I paint directly over old primer?

It depends on the condition of the old primer. If it is fully cured, smooth, and well-adhered, you can often scuff it with sandpaper and apply your topcoat. However, if the old primer is cracking, peeling, or of an unknown type, it is safest to sand it down or remove it completely. Applying new paint over a compromised foundation will not last. Our paint stripping products can help if removal is necessary.

What colour primer should I use?

The primer colour can significantly impact your final topcoat. A neutral grey primer is a versatile choice for most colours. For bright colours like yellows and reds, a white primer can make them appear more vivid. For dark or metallic colours, a black primer can add depth and richness. Our colour matching experts can recommend the best primer colour for your chosen paint.

Do I need to sand primer before painting?

Yes, in most cases, you must sand primer before applying the topcoat. Sanding serves two crucial purposes. First, it creates a perfectly smooth and flat surface by removing minor imperfections. Second, it creates a "key" or mechanical grip for the basecoat to adhere to, which prevents peeling. The only exceptions are some "wet-on-wet" sealers designed to be top-coated without sanding. For most primers, especially high-build surfacers, sanding with 400 to 600 grit sandpaper is a non-negotiable step. We offer a wide range of sanding sheets and sanding repair blocks to help you achieve a perfect surface.

Get Expert Advice for a Professional Result

Choosing the right auto paint primer is the foundation of a durable, professional finish. Understanding the roles of epoxy, urethane, and etch primers, along with the differences between 1K, 2K, and high-build formulas, empowers you to select the best product for your project.

For over 34 years, Eastern Auto Paints has been the trusted supplier for professionals and enthusiasts across Melbourne, Sydney, and Queensland. We stock premium brands like PPG Industrial Paints, Protec, Concept Paints, Jotun, Upol, Car rep, but our true value lies in our expert staff. We provide solutions, not just products, with advanced colour-matching technology and a comprehensive inventory that includes everything from our best-selling EPO 2K Primers to our Sata spray guns and PPE.

Don't let the complexity of choosing a primer hold you back. We are here to simplify the process and guide you to a flawless finish. Explore our complete range of primers and fillers, or contact us today for personalised, expert advice.