How to Never Worry About Applying Automotive Clear Coat Again

Share

Why Your Car's Finish Depends on This Final Layer

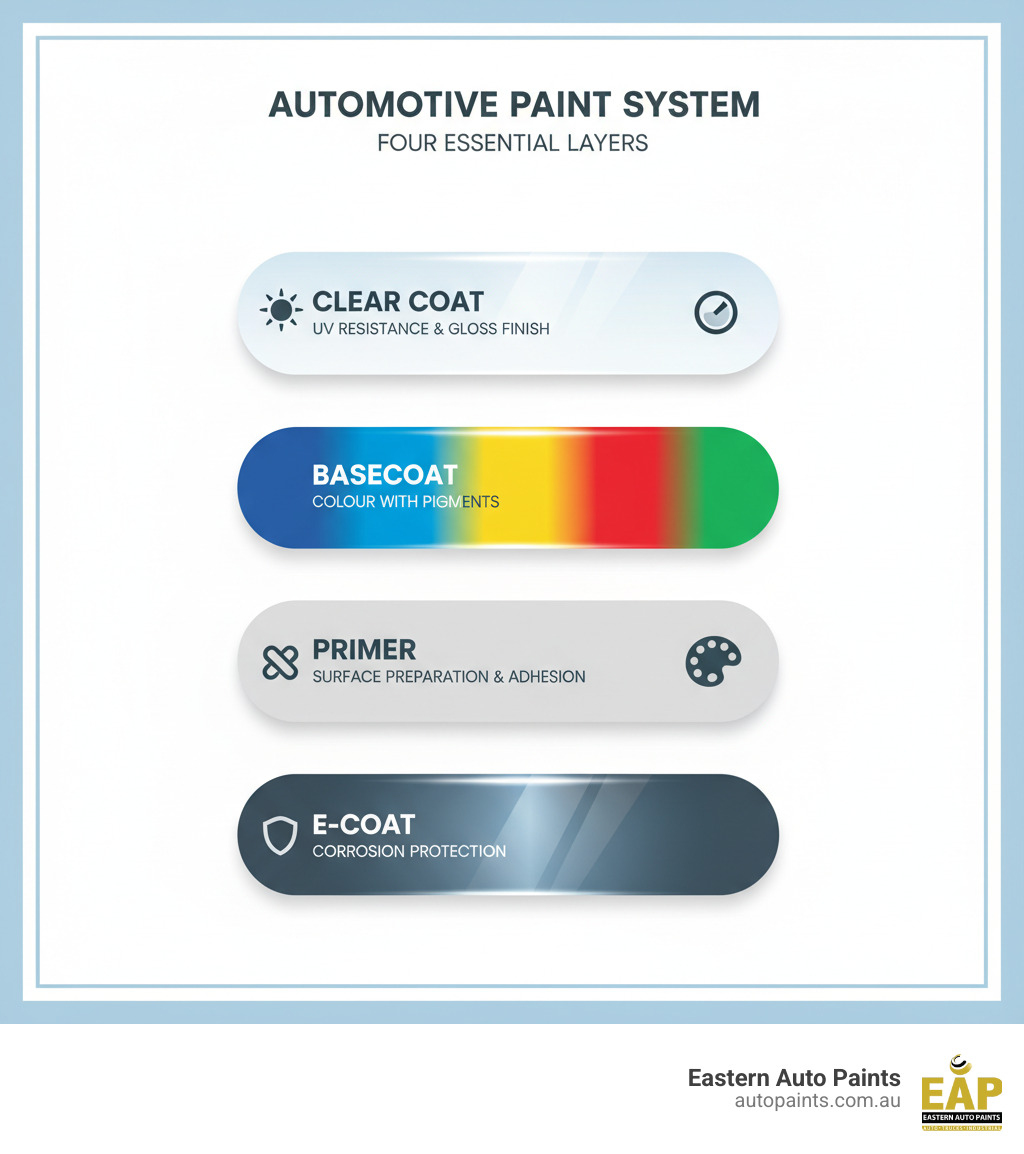

Automotive clear coat is the transparent protective layer applied over your vehicle's basecoat paint. It acts as a shield, protecting the colour from UV rays, chemicals, and scratches while providing a deep, glossy finish. Without it, a car's paint would fade and deteriorate in months, not years.

Key facts about clear coat:

- Composition: Typically acrylic-polyurethane resins with UV inhibitors.

- Types: Available as 1K (single-component, air-dry) or 2K (two-component with hardener, more durable).

- Thickness: Part of a total paint system around 100 to 125 micrometres (0.1mm-0.125mm thick.

- Lifespan: Can last 10-15 years with proper care.

2K clear coat technology has evolved significantly since it became standard in the 1990s, replacing older single-stage paints that oxidised quickly. Modern clear coats are essential for achieving a professional, long-lasting finish, whether you're doing a small touch-up or a full restoration.

I'm James Maranis, owner of Eastern Auto Paints. With over 30 years in the industry, I've seen how understanding clear coat science and application separates a finish that lasts a decade from one that fails in months. This guide shares that expertise to help you achieve showroom-quality results.

The Science and Evolution of Your Car's Top Layer

Your car's automotive clear coat is an engineered protective system, refined over decades to handle everything from the harsh Australian sun to road chemicals. While the basecoat provides colour, the clear coat takes the punishment, keeping that colour vibrant.

What is Automotive Clear Coat and What Does It Do?

Automotive clear coat is a transparent resin layer that acts as a sacrificial barrier between your car's colour and the world. Without it, UV rays would break down paint pigments, and chemicals would etch the surface. The clear coat absorbs this damage so the colour beneath remains intact.

Beyond protection, it provides the deep, glossy finish that makes colours pop and creates the "wet look" on a detailed car. This gloss directly impacts resale value. Modern automotive paint is applied in layers, with a total thickness of about 100 to 125 micrometres (0.1mm - 0.125mm). The clear coat itself accounts for a significant portion, typically 40-50 micrometres.

The Chemistry Behind the Shine

The magic of automotive clear coat is its chemistry. Most modern clear coats use an acrylic-polyurethane blend, combining the clarity of acrylics with the hardness and flexibility of polyurethanes. Key components include:

- Resins: The backbone of the coating, determining hardness, flexibility, and adhesion.

- Solvents: Dissolve the resins for smooth application and evaporate during drying.

- Additives: Fine-tune performance, helping the coat level out and preventing runs.

- UV inhibitors: Absorb harmful ultraviolet radiation, preventing the paint from fading and chalking.

When a two-component (2K) clear coat is mixed with its hardener, a chemical reaction called cross-linking creates a dense, durable network. This is why 2K systems offer superior resistance to chemicals and scratches compared to single-component (1K) systems that simply air-dry.

Paint technology has evolved from early lacquers and enamels containing toxic heavy metals. Environmental regulations pushed the industry toward safer, better-performing alternatives. Today's advanced clear coat systems deliver better results with far less environmental impact, capable of lasting 10-15 years with proper care.

At Eastern Auto Paints, we've seen this evolution over 34 years. The clear coats we supply from brands like PPG and Protec represent the cutting edge of this chemistry.

Choosing the Right Type of Automotive Clear Coat

Selecting the right automotive clear coat means matching the product to your project. At Eastern Auto Paints, our 34 years of experience can help you steer these choices to avoid frustration and wasted money.

The first choice is aesthetic. Gloss finishes offer a classic, mirror-like shine. Matte finishes provide a modern, non-reflective look that emphasizes body lines, while Satin finishes offer a subtle sheen that splits the difference. For metallic and pearl paints, a high-quality clear coat is critical to allow the special-effect pigments to sparkle and shift colour correctly.

Understanding 1K vs. 2K Automotive Clear Coat

The most important technical decision is choosing between 1K and 2K systems, as this dictates durability and performance.

One-component (1K) clear coats are ready to use from the can and cure by air-drying. They are convenient for small repairs and DIY projects but lack the chemical resistance and durability of 2K systems.

Two-component (2K) clear coats are the professional standard. They require mixing the clear coat with a hardener, which triggers a chemical reaction (cross-linking) to create a tough, durable finish. This process results in superior hardness, scratch resistance, and protection against chemicals and UV damage.

| Feature | 1K Clear Coat | 2K Clear Coat |

|---|---|---|

| Durability | Good for minor repairs, less resistant to chemicals and scratches | Excellent, highly resistant to chemicals, scratches, and UV damage |

| Application | Easy, single component, air-dry | Requires mixing with hardener, chemical cure |

| Curing | Air-dry (solvent evaporation) | Chemical reaction (cross-linking), air dry although process can be accelerated by heat |

| Cost | Generally lower initial cost | Higher initial cost but offers better value long-term |

| Typical Use | Touch-ups, small repairs, DIY projects | Touch ups, small repairs, professional refinishing, full repaints, high-durability applications |

For professional work, we always recommend 2K systems. You can browse our 1K clear coats for small jobs or our professional-grade 2K clear coats for projects that need to last.

Solvent-borne clear coats use organic solvents and are known for excellent flow and high-gloss finishes, but they release Volatile Organic Compounds (VOCs).

The Professional Application Process from Factory to Refinish

Applying automotive clear coat is where science meets art. Precision is key, whether in a factory or a professional spray booth. A great application results in a glass-like finish, while a poor one leads to defects and premature failure.

In OEM factories, robots apply consistent coats before baking the car at high temperatures (around 140°C or 284°F). Refinish shops work on assembled vehicles that can't handle such heat, which is why 2K clear coats are used, as they cure chemically. The fundamentals, however, are the same: meticulous preparation, proper mixing, controlled application, and adequate curing.

Before spraying, the surface must be cleaned and sanded. We stock a full range of - sanding discs and sheets for this crucial step. Application typically involves 2-3 coats, starting with a light tack coat followed by full wet coats, with a 5 - 10 minute flash-off time between each. Your spray gun settings are also vital. Professionals use HVLP (High-Volume Low-Pressure) or LVLP guns for efficient atomisation with minimal overspray. You can find suitable equipment in our selection of spray guns.

Applying Clear Coat to Different Substrates

Your approach must adapt to the surface. Metal panels are straightforward after proper prep. Plastic components like bumpers require a different strategy. They flex, so adhesion promoters are needed to bond the paint to the plastic. Flex additives are also often added to the primer and clear coat to prevent cracking.

Plastics also can't handle high heat, warping above 60-70°C (140-158°F). This is another reason 2K clear coats are standard for plastics, as they cure at lower temperatures. To speed up curing safely, many shops use infrared heat lamps.

How Technique Affects the Final Finish

Even with the best products, poor technique will ruin the result. Key variables include:

- Spray Distance: Maintain 15-20 centimetres (six to eight inches) from the surface. Too close causes runs; too far causes a textured "orange peel" effect.

- Overlap: Overlap each pass by 50-75% to ensure uniform film thickness.

- Gun Speed: Move at a steady, controlled pace (about one metre per second) without hesitation.

Getting these right prevents common defects like runs, sags, and orange peel. A poorly applied coat not only looks bad but also compromises durability, creating weak spots where moisture can penetrate or UV rays can attack the basecoat. At Eastern Auto Paints, our experts can guide you on product selection and technique to ensure a factory-quality result.

Protection, Damage, and Long-Term Maintenance

A properly applied automotive clear coat is your vehicle's first line of defence against the Australian climate. Understanding how to maintain it can mean the difference between a finish that lasts a decade and one that fails in a few years.

The clear coat's most critical function is UV ray protection, acting like sunscreen for your paint to prevent fading. It also provides chemical resistance against acidic contaminants like bird droppings and tree sap. Finally, it offers a degree of scratch resistance against minor abrasions and swirl marks from washing.

How to Spot Clear Coat Damage

Catching damage early can save you from an expensive repaint. Look for these common signs:

- Peeling or flaking: The clear coat is visibly lifting from the basecoat, indicating adhesion failure.

- Fading and oxidation: The paint appears dull and chalky, especially on horizontal surfaces like the bonnet and roof.

- Cloudiness or haziness: A milky film over the paint, which can indicate trapped moisture or chemical damage.

- Spiderweb cracks: Fine lines across the surface, often caused by extreme temperature changes.

- Dull spots: Areas where the gloss has disappeared, often from contaminants left on the surface too long.

Best Practices for Maintaining Your Automotive Clear Coat

Consistent care will dramatically extend the life of your finish. Follow these simple habits:

- Wash Properly: Hand wash your vehicle weekly with a pH-neutral car soap and soft microfibre mitts. Avoid washing in direct sunlight.

- Wax and Seal: Apply a quality car wax or paint sealant every two to three months. This adds a sacrificial layer of protection.

- Polish with Care: Use a fine polish to restore gloss. Use aggressive compounds sparingly, as they remove a thin layer of the clear coat.

- Avoid Harsh Chemicals: Stick to automotive-specific cleaners. Household products can strip wax and damage the clear coat.

- Remove Contaminants Promptly: Clean off bird droppings, tree sap, and bug splatter as soon as possible, as their acidity can etch the finish.

With over 34 years in the industry, we've seen proper maintenance keep a clear coat looking new for 15-20 years or more, while neglect can cause failure in just three to five. Regular attention protects your vehicle's appearance and its value.

Advanced Considerations and Future Trends

The world of automotive clear coat technology is constantly evolving due to environmental regulations and consumer demand. Understanding these trends helps you make informed decisions for any project.

OEM vs. Aftermarket Clear Coats

Factory (OEM) and aftermarket clear coats are optimised for different environments. OEMs use robotics and can bake 2K clear coats on metal panels at high temperatures (around 140°C or 284°F) for exceptional hardness. Aftermarket shops can't use such high heat on assembled vehicles, so they rely on 2K clear coats that cure chemically to achieve professional-grade durability.

At Eastern Auto Paints, we supply products like Protec Automotive Paint Systems, which are formulated to deliver factory-quality results in a refinish environment.

Latest Innovations and Trends

The future of automotive clear coat is exciting. Key innovations include:

- Self-healing clear coats: These contain polymers that can flow back together when heated, effectively erasing minor scratches.

- Ceramic-infused clear coats: Incorporating ceramic nanoparticles creates exceptional scratch resistance and hydrophobic (water-beading) properties.

- Advanced aesthetics: Matte and satin finishes are now mainstream, and new textured clear coats are emerging that offer unique tactile effects.

At Eastern Auto Paints, our partnerships with leaders like PPG and Concept Paints ensure we offer the latest innovations. Our expert staff can guide you to the right product, whether you need cutting-edge technology or a proven traditional formula.

Frequently Asked Questions about Automotive Clear Coats

With over three decades of experience, we've answered nearly every question about clear coats. Here are the most common ones we get at Eastern Auto Paints.

How many coats of clear coat are needed for a durable finish?

The industry standard is 2-3 coats. This provides sufficient film thickness for protection against UV rays and minor scratches. Some high-solid clear coats may only need two coats. Always check the manufacturer's Technical Data Sheet (TDS) for the precise recommendation for the product you are using.

How long does 2K clear coat take to cure?

There's a difference between drying and curing. A 2K clear coat is typically tack-free (dry to the touch) in 30 minutes to a few hours. However, a full cure, where it reaches maximum hardness and chemical resistance, takes 24-72 hours at room temperature (around 20°C or 68°F). For best results, wait 30-45 days before waxing or aggressive washing.

Professional shops use baking or infrared heat lamps to reduce the full cure time to a few hours.

Can you apply a new clear coat over an old one?

Yes, but only if the existing clear coat is in good condition (not peeling, flaking, or severely cracked). Preparation is critical. You must thoroughly clean and then sand (or "scuff") the old clear coat with fine-grit sandpaper (800-1000 grit). This creates a mechanical bond for the new coat to adhere to. If you skip this step, the new clear coat will peel. If the existing damage is severe, you must strip the old clear coat completely to ensure a stable foundation for the new paint system.

Achieve Professional Results with Expert Knowledge

Understanding automotive clear coat comes down to three key areas: the advanced chemistry in the can, the meticulous application process, and the consistent care required for a long-lasting finish. From choosing between 1K and 2K systems to mastering your spray technique, every step contributes to the final result.

At Eastern Auto Paints, we've spent 34 years helping professionals and enthusiasts across Australia achieve superior results. Our team understands the challenges of the local climate and only the most reliable high quality and affordable products, including PPG and Protec, auto,commercial and industrial range, as well as Concept Paints full range of auto and industrial.

For a finish that turns heads and stands the test of time, you need quality products and expert advice. Our advanced colour-matching technology and experienced staff ensure you get exactly what you need for your project.

For professional-grade products and guidance, explore our complete selection or contact our team today.