The Ultimate Guide to Powder Coat Colour Options

Share

Why Choosing the Right Powder Coat Colour Matters

Choosing a powdercoat colour is more than just an aesthetic decision. It directly impacts your product's durability and performance. Key considerations include the finish type (like gloss, matte, or textured), environmental protection needs (such as UV resistance and corrosion resistance), and adherence to industry standards. For example, AS3715, the Australian Standard for powder coating metal, ensures consistent quality and longevity.

Powder coating offers significant advantages over traditional liquid paint. It provides a thicker, more durable finish with superior resistance to chipping, scratching, and fading. Because it contains no volatile organic compounds (VOCs), it is also an environmentally responsible choice for automotive and industrial applications.

Modern powder coating technology offers hundreds of colours and finishes. The range includes everything from warranty-grade architectural finishes to specialised automotive colours, textured surfaces with exceptional scuff resistance, and even sublimation basecoats that mimic natural materials like wood or stone.

I'm James Maranis, and with over 30 years in the coatings industry, I've worked on countless powdercoat colour applications for automotive, industrial, and architectural projects. This guide uses that experience to help you steer the technical and aesthetic choices in powder coating selection. At Eastern Auto Paints, a Melbourne born supplier serving Australia-wide, we combine advanced colour-matching technology with our role as a certified distributor for leading brands like Jotun and PPG to ensure you get the right system, backed by expert advice.

Exploring the Spectrum: Types of Powder Coat Finishes

The beauty of powdercoat colour selection lies in the variety of available finishes, each combining visual appeal with practical benefits. Understanding these options helps you choose the right one for your project's form and function.

Standard Finishes

Standard finishes are the foundation of powder coating, delivering consistent and reliable results.

- Gloss finishes create a mirror-like, reflective surface that makes colours appear intense and professional.

- Satin finishes offer a subtle, sophisticated sheen that is versatile and better at hiding minor surface imperfections than high gloss.

- Matte finishes absorb light for a flat, non-shiny appearance that feels modern and excels at concealing surface irregularities.

Textured and Effect Finishes

Beyond standard gloss levels, textured and special effect finishes can mimic natural materials or add functional benefits.

- Highly durable textured finishes are engineered for performance; super tough and resistant to scratches and marks.

- Metallic and pearlescent finishes incorporate reflective particles to create shimmering effects that change with the light, adding depth and a premium feel.

- Ripple and hammer effects create distinctive undulating patterns that conceal surface imperfections and add character, popular for decorative metalwork.

- Anodised-look finishes deliver the sophisticated appearance of anodised metal without the complex process, offering a modern aesthetic that subtly changes with lighting conditions.

- Sublimation basecoats allow powder-coated metal to mimic natural wood or stone. This provides the beauty of natural materials with the durability of powder-coated metal.

Our Textured Powdercoat Colours collection showcases the full range of possibilities. With 34 years of experience serving Melbourne and Australia-wide, we can help you select the perfect finish.

Beyond the Hue: Durability, Protection, and Your Powdercoat Colour

Selecting a powdercoat colour is also about performance. The technical properties of the powder determine how well it protects your investment and maintains its appearance for decades.

Protection for Any Environment

Powder coating is formulated to handle diverse conditions, from controlled indoor environments to the harsh Australian sun and coastal salt spray.

- High ultraviolet (UV) resistance is critical for outdoor applications to prevent colours from fading and chalking. Advanced fluoropolymer powders offer superior UV protection, ensuring colour vibrancy even under intense sun.

- Impact and abrasion resistance comes from the thick, resilient layer that shields against scratches, dents, and daily wear, making it ideal for industrial equipment and high-contact surfaces.

- Corrosion and chemical protection is a key advantage. The coating creates an impermeable barrier against moisture, chemicals, and salt. Zinc-rich epoxy modified powders can be used as a protective undercoat to inhibit rust on ferrous metals. For more options, see our Rust Repair & Prevention products.

Powder Chemistries

A powder's chemical makeup determines its performance. Knowing the key types guides you to the right choice for your project. Different powders suit different jobs: some last longer outside, some resist chemicals, and some are great indoors.

- Thermosetting powders undergo a chemical change during curing, creating a hard, cross-linked film that will not re-melt, providing superior durability.

- Polyester-based powders offer a great balance of weatherability and mechanical properties for both indoor and outdoor use. Super durable polyester formulations provide even greater longevity for architectural applications.

- Epoxy powders excel in chemical and corrosion resistance, making them effective primers. However, they tend to chalk in UV light and are best for interior use or as a basecoat.

- Fluoropolymer-based powders represent the pinnacle of weatherability and UV resistance, specified for high-end architectural projects where long-term colour retention is critical.

Finding Your Perfect Shade: The Art and Science of Colour Selection

Achieving the perfect colour involves understanding the limitations of digital displays and the importance of physical samples to ensure accuracy.

How to Get Your Powdercoat Colour Right

Have you ever ordered a powdercoat colour that looked perfect online, only for it to arrive in a different shade? This is a common issue caused by variations in screen resolution, brightness, and display settings.

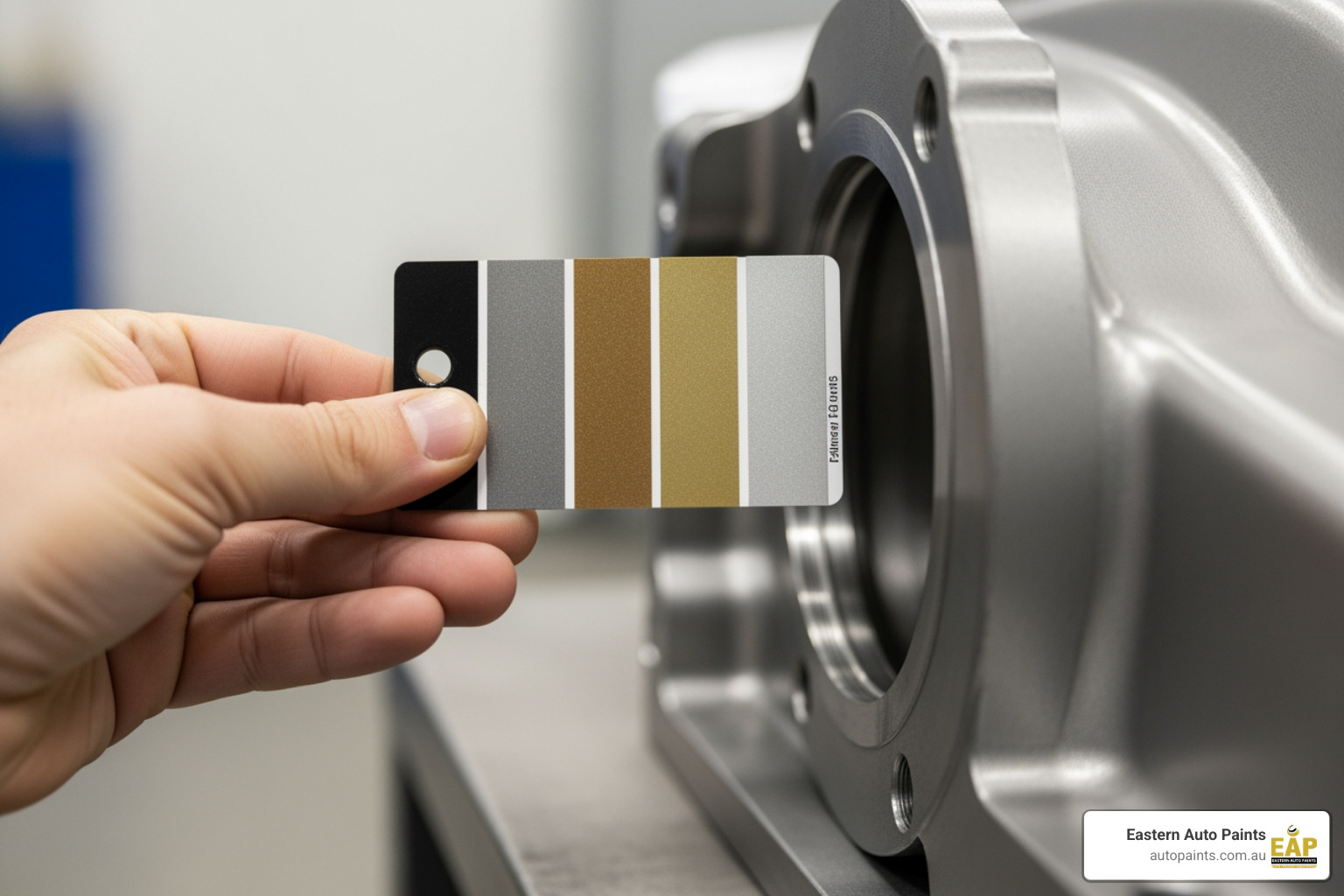

Physical swatches are essential for accurate colour decisions. These powder-coated aluminium panels show the true colour, texture, and sheen. Always confirm your choice with a production line prepared swatch for final approval to avoid costly mistakes.

To select a colour effectively:

- Start by browsing online charts to narrow your options.

- Order physical swatches of your top contenders.

- Evaluate the swatches in the actual lighting conditions where the final product will be used. A colour can look dramatically different under workshop fluorescents versus natural daylight.

Our team at Eastern Auto Paints has over three decades of experience and can provide expert guidance to help you select a colour with confidence.

Custom and Industry-Specific Colours

When a standard colour isn't enough, custom matching services are invaluable for matching a brand identity or bringing a unique design to life.

The custom powdercoat colour matching process uses advanced digital tools to measure colour, gloss, and texture, allowing us to replicate almost any shade. This is especially useful for large commercial builders needing unique offerings for specific architectural designs.

- For architectural applications, popular ranges like COLORBOND® steel colours are widely used for their proven performance. These ranges often adhere to strict standards like AAMA and AS3715, ensuring long-term durability.

- In the automotive sector, precise colour matching is crucial for repairs. We use advanced technology to create exact matches for a vehicle's factory paint, ensuring seamless results.

- For industrial coatings, the focus is on both aesthetics and performance, with specific colours often required to meet functional and branding needs across different products.

We can also provide custom aerosol solutions for touch-ups. It is important to note that while we can create custom aerosols to match Jotun powdercoat colours, these are custom-made by Eastern Auto Paints and are not an official Jotun product.

Staying Ahead of the Curve: Powder Coat Colour Trends and Innovations

The world of powder coating is always evolving with new colours, effects, and technologies. Staying current allows us to offer the most innovative solutions for your automotive, architectural, or industrial projects.

The Latest in Colour and Finishes

Colour influences how we perceive spaces and objects. In powder coating, the creative possibilities continue to expand.

Each year, manufacturers release trend collections reflecting global design shifts. For 2025, Dulux announced 'True Joy' as its Colour of the Year, a warm, optimistic gold. It's worth noting that other companies often present their own distinct colour picks. Current trends continue to draw heavily from nature, with earthy tones, natural metallics, and stone-effect finishes remaining popular for their authentic, grounded aesthetic.

One of the most exciting developments is sublimation technology. Using specialised basecoats, you can achieve realistic wood grain effects on metal, offering the warmth of timber with the durability of a powder-coated finish. This is ideal for applications where actual wood is not practical.

We encourage you to explore our powder coating range to find on-trend palettes and finishes that suit your project and environment.

Technological Advancements

Behind every great finish is technological innovation that makes the coating process more efficient and environmentally responsible.

Powder formulations are continuously refined for better flow, coverage, and resistance to chemicals and abrasion. A key breakthrough is low-cure temperature powders, which cure at lower temperatures or faster speeds. This saves energy and allows heat-sensitive materials to be coated.

Digital visualisation tools are also narrowing the gap between design and reality. Platforms that render hyper-realistic 3D views of coatings help you see how different finishes will look on your project, which streamlines selection and reduces mistakes.

At Eastern Auto Paints, we work with leading manufacturers to ensure you have access to the most advanced powder coating products available.

Frequently Asked Questions about Powder Coat Colours

After three decades in the business, we've heard a lot of questions about powdercoat colour and its applications. Here are answers to the most common ones.

How long does powder coating last?

Properly applied powder coating is remarkably long-lasting, typically for 15 to 20 years. With the right chemistry and preparation, some finishes can last even longer, especially when applied over correctly prepared galvanised steel.

Longevity depends heavily on two factors:

- Surface preparation is critical. Proper cleaning, degreasing, and pre-treatment are essential for adhesion and corrosion protection. Skipping these steps will lead to premature failure.

- Environmental factors matter. For sunny or coastal areas, a powder with high UV resistance (like a fluoropolymer) is necessary to prevent fading. For industrial or marine environments, coatings with improved corrosion protection are vital.

Can you powder coat over an existing finish?

You can powder coat over existing finishes, but compatibility, adhesion, and the old coating's condition are critical. Your new finish is only as good as the layer beneath; if it fails, your new coat will too. For highest longevity, stripping to bare metal is the safest practice.

Furthermore, the high curing temperatures (typically 180 to 200 degrees Celsius) can cause old paint to bubble or off-gas, creating defects in the new powder coat. Doing the prep work right the first time is always the most cost-effective solution.

Is powder coating better than liquid paint?

For most industrial, automotive, and architectural applications, powder coating offers clear advantages over liquid paint.

- Durability and Thickness: Powder coating creates a thicker, more uniform film (typically 50 to 200 microns) that provides superior resistance to chipping, scratching, and abrasion.

- Environmental Benefits: It contains no volatile organic compounds (VOCs), making it safer for applicators and the environment.

- Coverage on Complex Shapes: The electrostatic application process ensures the powder wraps around edges and into recesses for uniform coverage without runs or drips.

Liquid paint's main advantage is the ease of spot repairs. However, for comprehensive, long-lasting protection, powder coating is the more robust solution. Our team at Eastern Auto Paints can help you weigh the options for your specific project. Contact us for expert advice.

Bringing Your Vision to Life with the Right Colour

We hope this guide has shown the diverse world of powdercoat colour. From sleek matte and brilliant metallic finishes to durable textured and realistic wood-look effects, there is a solution for every project.

Choosing the right colour means balancing aesthetics with technical properties like UV resistance, impact resistance, and corrosion protection. Understanding powder chemistries and the importance of physical swatches ensures your finish looks great and performs for years. With custom colour matching, your vision is never limited by a standard catalogue.

At Eastern Auto Paints, we have supplied high-quality industrial and automotive coatings to professionals across Victoria, Sydney, and Queensland for over 34 years. Our Melbourne-based team combines decades of experience with advanced colour-matching technology, making us a trusted partner for projects of any scale. We provide the expert guidance you need to steer the options and make confident decisions.

Ready to find the perfect finish? Find the perfect powder coating for your project through our comprehensive range, or Contact Us for expert advice to turn your vision into reality.