Understanding Hammertone Paint Colours Suppliers and Finishes

Share

Why Hammertone paint colours are so popular

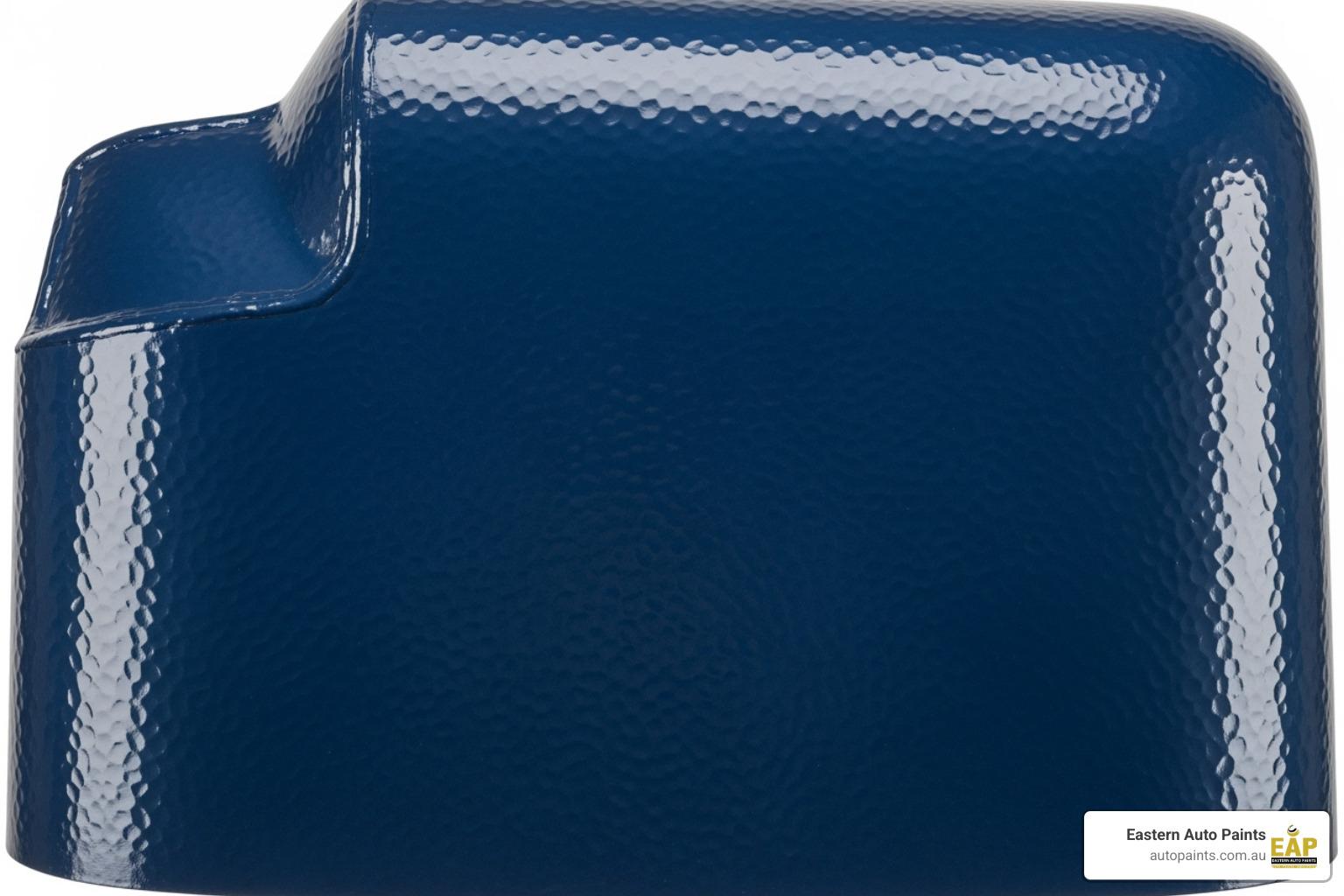

Hammertone paint colours provide a unique textured finish, combining industrial durability with an attractive hammered metal look. For projects ranging from classic car restoration, trailers and finishing metal railings, choosing the right colour and finish is key to achieving both protection and aesthetics.

Quick Guide to Hammertone Paint Colours:

| Aspect | Key Information |

|---|---|

| Popular Colours | Silver, Charcoal, Steel Grey, Bronze, Copper, Various Greens and Blues |

| Common Finishes | Hard gloss (most common), Some matte options available |

| Primary Applications | Metal equipment, Trailers, Automotive trim, Industrial machinery, Workshop tools |

| Key Benefits | Hides surface imperfections, Corrosion resistant, Minimal surface prep required |

| Application Methods | Spray gun (best results), Brush or roller (touch-ups) |

The distinctive hammered texture serves a practical purpose by camouflaging dents, scratches, and other surface flaws that would show through regular paint. This means you can often skip extensive sanding, saving significant preparation time.

What makes hammertone different? The coating contains copolymer alkyd resin and pigmented with tinters and aluminium flakes . As the paint cures, these additives create the characteristic dimpled pattern that resembles hand-hammered metal, resulting in a hard, scratch-resistant finish.

With over 30 years in the coatings industry, our team at Eastern Auto Paints has helped countless professionals select the right hammertone paint colours for everything from vintage car dashboards to heavy industrial equipment. We stock trusted brands like PPG Hammertone in a full spectrum of mixed colours, ensuring you get the exact finish your project demands.

What is Hammertone Coating and How is the Effect Created?

Hammertone coating is a specialist paint that creates a textured finish resembling hand-hammered metal, delivering both visual appeal and serious protection for metal surfaces.

Unlike standard paints, which aim for a smooth finish, hammertone coatings intentionally create a dimpled pattern. The difference lies in the formulation. Unlike conventional paints, hammertone coatings contain specific additives that react during the curing process to form the distinctive hammered effect.

The Science Behind the Hammered Finish

The hammered texture is created by a precise chemical formulation. Three key ingredients work together to create the pattern.

Concentrated tinters and aluminium flakes are finely ground and suspended in the paint. As the paint dries, they align to reflect light from multiple directions, creating depth and a metallic sheen. These minerals also reinforce the dried film, making it harder and more scratch-resistant.

Decorative and Protective Properties

Hammertone is a true dual-function coating, delivering aesthetic improvement and robust protection in a single application.

Decoratively, it creates an attractive industrial look that adds character to otherwise plain surfaces. The range of hammertone paint colours available means you can achieve this finish in shades from classic silver to bold copper.

The protective benefits are equally impressive. Hammertone paints offer excellent corrosion resistance, especially when applied over a suitable primer. The hard, glossy finish provides outstanding scratch resistance that preserves the appearance of coated surfaces.

Perhaps its most practical advantage is the ability to hide surface imperfections. The textured finish camouflages minor flaws like welding seams, dents, and scratches. This often eliminates the need for extensive surface preparation, saving considerable time and effort.

High-quality hammer finish enamels also offer improved exterior durability and UV protection, ensuring colours and protective qualities last, even in harsh Australian weather. While primarily for metal, these coatings can also be applied to certain plastics and woods when used with a suitable bonding primer.

Exploring the Spectrum of Hammertone Paint Colours and Finishes

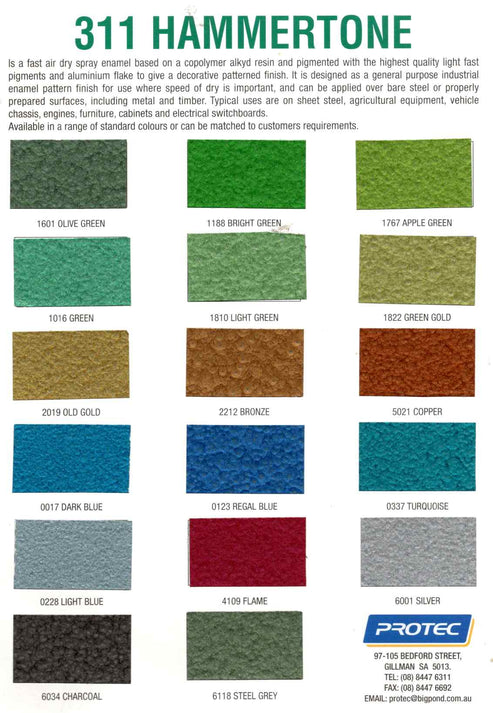

While classic silver and grey remain popular, the spectrum of hammertone paint colours has expanded significantly. Modern formulations offer a diverse palette, all featuring the metallic shimmer that defines the hammered texture.

Common Hammertone Paint Colours

Quality hammertone formulations offer a wide breadth of choice beyond the classics. Popular options include:

- Classic Metallics: Silver, Charcoal, and Steel Grey for a traditional industrial look.

- Warm Tones: Gold, Bronze, and Copper provide vintage or earthy metallic sheens, ideal for restoration and ornamental work.

- Greens: A range from Olive Green for classic equipment to brighter Apple Green and Green Gold for modern designs.

- Blues: Dark Blue and Regal Blue for commercial equipment, or cooler Turquoise and Light Blue for decorative or marine applications.

- Bold Shades: Eye-catching colours like Flame for statement pieces.

At Eastern Auto Paints, we supply PPG Hammertone Mixed Colours in an extensive range of shades.

Gloss finishes are the standard for hammertone coatings. The hard, glossy surface reflects light across the textured dimples, accentuating the hammered effect and creating visual depth. Beyond aesthetics, gloss finishes are easier to clean, more resistant to staining, and typically offer superior scratch resistance. This finish delivers the classic look and robust protection expected from a traditional hammertone coating.

Key Advantages and Applications for Hammertone Coatings

Hammertone paint colours offer practical advantages that save time, cut costs, and deliver lasting results. With over 30 years of experience, our team at Eastern Auto Paints has seen why these finishes are a go-to choice for real-world applications.

The primary advantage is surface forgiveness. Hammertone camouflages imperfections like welding seams, dents, and scratches, often eliminating the need for extensive sanding. This saves significant time, a crucial benefit for busy workshops and large industrial jobs.

According to the Technical Data Sheet for Hammer Finish Enamel, these coatings provide excellent corrosion resistance and a hard, durable finish that stands up to harsh Australian conditions. The textured surface also offers natural slip resistance. When applied correctly, hammertone coatings provide UV protection and exterior durability for a long-lasting professional look.

Industrial and Commercial Uses

In heavy-duty environments, hammertone coatings prove their worth with a combination of toughness and professional appearance.

- Trailers: The coating withstands vibration, weather, and scrapes, making it ideal for utility and transport trailers. We supply these products throughout Australia.

- Metal Railings and Fencing: The hammered texture provides robust rust protection while complementing architectural metalwork.

- Industrial Machinery: Hammertone protects pumps, compressors, and factory equipment from corrosion and wear, resisting scratches from tools and contact.

- Toolboxes and Storage Units: The scratch-resistant quality keeps workshop storage looking professional despite daily handling.

- Structural Steel: The coating adheres well to prepared steel, providing a uniform, protective, and industrial look.

- Workshop Equipment: Applying a hammertone finish to vices, drill presses, and workbenches extends their life and improves their appearance.

Our PPG Industrial Paints range includes professional-grade hammertone options designed for these demanding applications.

Automotive and Workshop Projects

At Eastern Auto Paints, our comprehensive automotive paint supplies include hammertone options suitable for everything from classic car restoration to modern customisation.

A Professional's Guide to Applying Hammertone Paint

Achieving a professional hammertone finish requires proper technique, but the paint is famously forgiving of minor surface flaws. Following these steps ensures the best results.

After 34 years supplying professional painters across Melbourne and beyond, we know the difference between a good finish and a great one comes down to fundamentals. Let's walk through the process.

Preparing Surfaces for Hammertone Paint Colours

Proper preparation is key, though hammertone is versatile enough for multiple substrates.

- Metal Surfaces (Steel, Iron, Aluminium): Start by removing all dirt, grease, and oil with a quality degreaser. Use a wire brush or chemical remover for loose rust and flaking paint. While hammertone hides minor pitting and grind marks, structurally compromised rust must be treated. For best adhesion, scuff smooth surfaces with 80-240-grit sandpaper to create a mechanical key.

- Priming Metal: While some Direct-to-Metal (DTM) hammertone paints exist, using an anti-corrosive primer provides far better long-term protection. Our range of 1K Primers works exceptionally well under hammertone finishes, especially for outdoor applications.

- Wood and Plastic Substrates: These materials require a suitable bonding primer to ensure proper adhesion. Follow the primer manufacturer's instructions for preparation, which typically involves light sanding.

Recommended Application and Cleanup

The application method directly affects the final texture.

- Spray Application: Using a professional spray gun delivers the most consistent and attractive hammered pattern. Apply two light coats with a 10-minute flash-off time between them, followed by one medium wet coat. This method builds the correct film thickness for a durable finish. We carry a selection of Spray Guns and Accessories, including trusted brands like Sata, Anest Iwata and Star spray guns

- Brush or Roller: This method is suitable for small touch-ups but will not produce the same pronounced hammered texture as spraying. The finish will still be protective but may appear less dimpled.

Drying and Coverage: Drying times vary, but finishes are typically touch-dry in 20-30 minutes. Full cure takes longer. 1 litre provides coverage of approximately 15 square metres . Always buy extra to avoid running out mid-project.

Cleanup and Safety: Use quality paint thinners or gun wash from our Hardeners, Reducers, and Solvents range for immediate cleanup of solvent-based hammertone. Always wear appropriate PPE masks and overalls and gloves when spraying solvent-based coatings.

Frequently Asked Questions about Hammertone Paint

Here are the answers to the questions we hear most often about hammertone paint colours from our customers at Eastern Auto Paints.

Is hammertone paint rust-proof?

Hammertone paint offers excellent corrosion resistance by creating a hard barrier against moisture. For maximum, long-lasting rust protection, especially on bare metal or in harsh environments, we always recommend using an anti-corrosive primer first. Our range of 1K Primers includes excellent anti-corrosive options for this purpose.

Always check the product's Technical Data Sheet (TDS) to confirm if priming is required for your specific application. With proper preparation and application, a hammertone system provides outstanding rust protection that lasts for years.

Can you apply a clear coat over hammertone paint?

Applying a clear coat over hammertone paint is not recommended. A clear coat can fill in the textured pattern, diminishing the signature hammered effect. It can also cause compatibility issues with the silicone and metallic additives in the paint, leading to poor adhesion, peeling, or clouding.

Quality hammertone paint colours are already formulated for durability, scratch resistance, and UV protection, making a separate clear coat redundant. If you believe your project requires a clear coat, consult the manufacturer's TDS or contact us for expert guidance. While we stock a full range of 2K Clear Coats, they are not typically suitable for this application.

A Complete Look at Hammertone Paint Colours

Choosing the right hammertone paint colours means understanding the coating's unique properties and practical applications. Its distinctive hammered look is created by a specific formulation that also delivers significant performance benefits. These include corrosion resistance, scratch protection, and the ability to camouflage surface imperfections, saving time on preparation.

The versatility of hammertone paint colours now extends far beyond traditional silver and charcoal to include warm bronzes, vibrant greens, and deep blues. Each colour maintains the characteristic hard, glossy finish that defines a quality hammertone coating, making it suitable for industrial machinery, automotive trim, and workshop equipment.

What truly sets hammertone apart is its forgiving nature and robust protection. It saves time and cost on restoration projects by hiding minor flaws, yet it provides long-lasting defence against harsh Australian weather and industrial wear when applied correctly.

At Eastern Auto Paints, our 34 years of expertise and partnership with trusted brands like PPG ensure we can supply the exact hammertone paint colours your project requires. We are more than a supplier; we are a technical resource for professionals across Victoria, Sydney, and Queensland seeking superior results.

For expert advice and to explore our complete range of custom PPG Hammertone Mixed Colours, visit our product page. Our team is ready to help you select the perfect colour and guide you through the application process for a finish that lasts.