PPE Masks Comparison 101

Share

Your Guide to Choosing the Right Respiratory Protection

Choosing the right PPE Masks is essential for protection against airborne hazards in automotive and industrial work. This guide clarifies the key differences to help you select the correct equipment.

| Mask Type | Filtration Efficiency | Primary Purpose | Best For |

|---|---|---|---|

| N95 Respirator | Minimum 95% | Protects the wearer | Workshop dust, particles, professional use |

| KN95 Respirator | Minimum 95% | Protects the wearer | Similar to N95, variable quality |

| Elastomeric Respirator | 95%+ (with proper cartridge) | Protects against particles, gases, vapors | Spray painting, isocyanate exposure |

| Surgical Mask | Variable (not rated) | Blocks droplets, protects others | Medical settings, source control |

| Cloth/Barrier Mask | 10-99% (highly variable) | Blocks droplets, protects others | General community use |

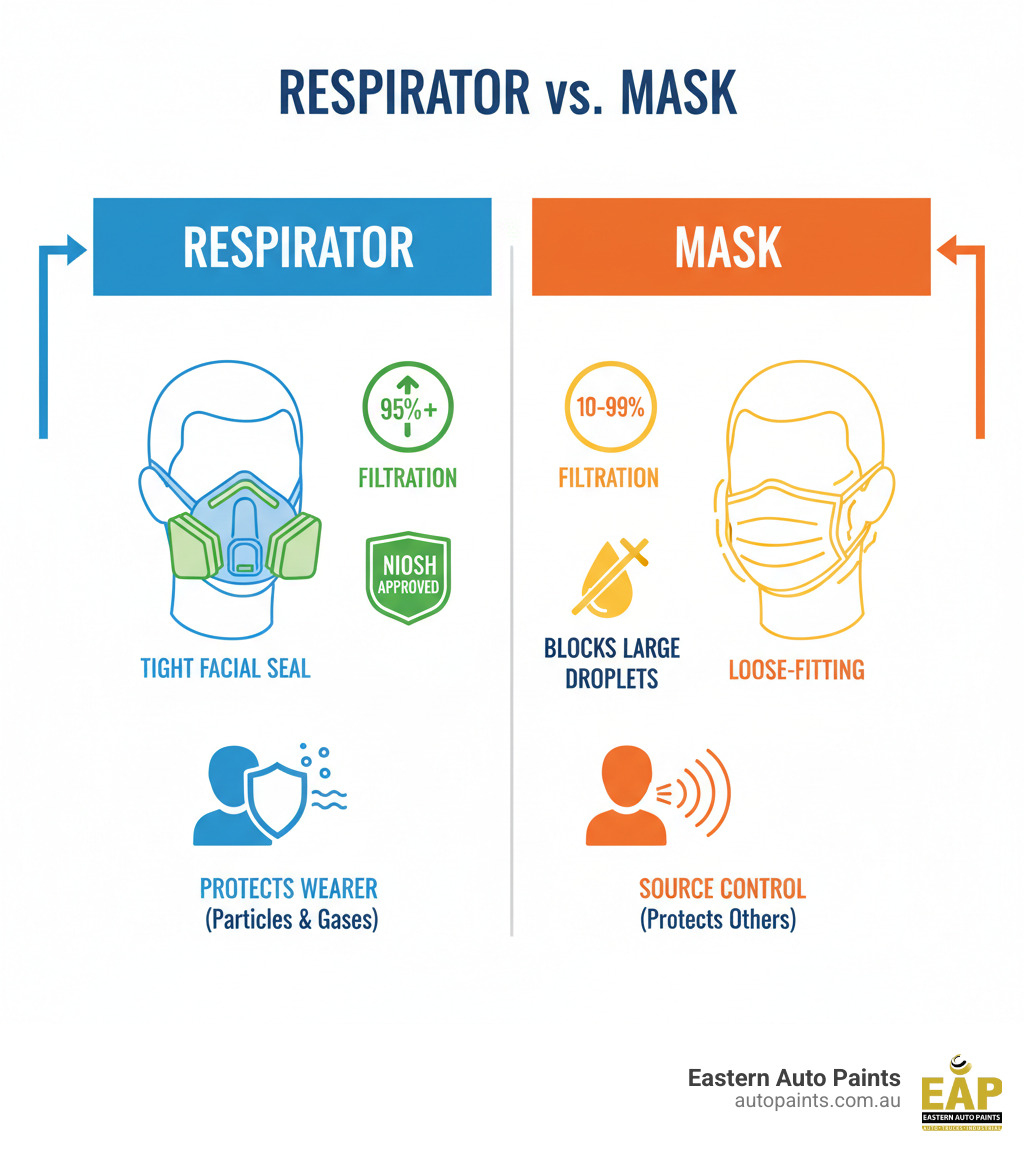

The key distinction is between respirators, which create a tight seal to filter the air you breathe, and masks, which are loose-fitting and mainly prevent you from spreading germs. For automotive work with paint, dust, or chemicals, a proper respirator is mandatory.

Using the wrong protection can lead to serious health risks. Hazards like paint overspray, body filler dust, and chemical vapours require specific levels of protection that a simple cloth or surgical mask cannot provide, especially when working with 2K paints or isocyanates.

With over 30 years in the coatings industry, I've seen the critical importance of proper respiratory protection. At Eastern Auto Paints, we stock professional-grade PPE Masks and respirators because we know that choosing the right protection isn't just about compliance, it's about your long-term health.

Understanding the Difference: Respirators vs. Masks

Understanding the difference between a respirator and a mask is key to protecting your health. While both cover your nose and mouth, their design, purpose, and level of protection are vastly different. This distinction is especially critical in automotive workshops across Victoria, where respiratory hazards like paint overspray, isocyanates, and sanding dust are common. Personal Protective Equipment (PPE) is your final line of defence, so getting it right is non-negotiable.

What is a Respirator?

A respirator is designed for serious protection. It creates a tight-fitting seal around your face to filter the air you inhale, protecting you from airborne particles, gases, and vapours. In occupational settings like automotive paint shops, respirators are essential.

Because air takes the path of least resistance, a snug fit is crucial. If there are gaps, contaminated air bypasses the filter. That's why these devices undergo rigorous testing. In the United States, the National Institute for Occupational Safety and Health (NIOSH) approves respirators for workplace use. The Assigned Protection Factor (APF) indicates how much a respirator reduces exposure, with a higher APF meaning better protection. The Occupational Safety and Health Administration (OSHA) requires employers to use NIOSH-approved respirators for respiratory hazards.

Bottom line: respirators are what you need when working with automotive paints, dust, and chemicals.

What is a Mask?

A mask, such as a surgical or cloth face covering, is loose-fitting and does not seal against your face. Its main job is source control, which means stopping droplets from leaving your mouth and nose to protect others from you. This is why the CDC recommends them for general public use.

While masks can block some larger droplets, their variable filtration efficiency (from 10% to 99%) and loose fit mean they offer minimal personal protection compared to respirators. There are often no specific regulations for disposable and cloth masks, making it hard to know what level of filtration you are getting.

For automotive work involving spray painting, sanding, or chemical exposure, a standard mask is inadequate. You need a genuine, NIOSH-approved respirator, not just a face covering.

Comparing High-Protection Respirators for Workshop Hazards

When spray painting, sanding, or mixing solvents, a basic face covering is not enough. The hazards in an automotive or industrial workshop demand high-protection respirators that meet rigorous filtration standards set by organisations like the National Institute for Occupational Safety and Health (NIOSH). The Occupational Safety and Health Administration (OSHA) mandates that choosing the right respiratory protection is essential for your long-term health when exposed to workplace hazards.

NIOSH-Approved N95 Respirators

The N95 respirator is a common choice for workshop protection. The "N" means "not resistant to oil," and the "95" signifies it filters at least 95% of airborne particles, including microscopic dust from sanding. A genuine N95 is NIOSH-approved, meaning it has passed comprehensive testing for filtration efficiency and manufacturing quality.

However, an N95 is only effective if it creates a tight seal against your face. If air leaks around the edges, you're breathing unfiltered air, rendering the 95% filtration useless. This is why professional fit testing is so important. N95s also have limitations: they are not designed for children, and facial hair like a beard or stubble will prevent a proper seal. To ensure you have an authentic product, check the NIOSH Certified Equipment List.

International Standards: KN95 and Others

KN95 masks are designed to meet Chinese standards, also aiming for 95% filtration. However, the key difference lies in the approval and quality assurance processes. International standards may have different testing protocols, and the manufacturing quality can be inconsistent. While some international respirators perform well, there is a higher risk of encountering products that fall short, including counterfeits. This means you need to be cautious about your source. For more context, the CDC offers a comparison of international filtering facepiece respirators. When sourcing PPE Masks, always prioritise suppliers who can verify authenticity.

Reusable Elastomeric Respirators: The Professional's Choice

For serious workshop hazards like automotive paints, solvents, and isocyanates, reusable elastomeric respirators are the professional standard. These durable respirators use replaceable cartridges and filters custom to specific hazards.

Available in half-face (covering nose and mouth) and full-face (also protecting eyes) configurations, they provide an excellent seal. You can select cartridges for organic vapours, particulates, or both. This modularity is essential for professional work.

Crucially, when spray painting with products containing isocyanates (common in 2K automotive paints), standard particulate respirators like N95s are often insufficient. Isocyanates are highly toxic, and for these applications, atmosphere-supplying systems like Air Fed Masks are often required for adequate protection. A workplace risk assessment is essential to determine the correct protection for your tasks. For more guidance, explore our articles on choosing a half-face respirator and understanding air-fed systems.

A Guide to General Use Face Coverings

Outside of the workshop, general use face coverings like surgical and cloth masks play a different role. They are primarily designed for source control, meaning they are better at stopping you from spreading germs than protecting you from inhaling hazardous substances. This makes them suitable for community settings but completely inadequate for environments with fine particles, paint fumes, or chemical vapours.

Surgical Masks

Surgical masks are loose-fitting, disposable coverings that create a physical barrier to block large-particle droplets and splashes. This fluid resistance makes them common in medical settings. Their main benefit is protecting others by catching droplets from a cough or sneeze. However, due to their loose fit and leakage around the edges, they are not effective at filtering small airborne particles and are not designed to protect the wearer from workshop hazards.

Barrier Face Coverings and Cloth Masks

The world of PPE Masks becomes more variable with barrier face coverings (BFCs) and cloth masks. Some BFCs meet the ASTM F3502-21 standard, which requires testing for filtration and leakage, with performance levels ranging from 20% to 80% filtration efficiency. You can find more information on the NIOSH Personal Protective Equipment Information page.

Cloth masks typically have no governing standards, and their filtration can range from 10% to 99% depending on the material, weave, and layers. Certifications like STANDARD 100 by OEKO-TEX may ensure the material is free of harmful chemicals but do not guarantee filtration performance.

The loose-fitting design of both BFCs and cloth masks makes them unsuitable for protecting against fine particulate matter, organic vapours, or isocyanates found in automotive workshops. They are best reserved for general community use where the goal is simply reducing the spread of respiratory droplets.

Essential Features and Best Practices for All PPE Masks

Even the best respirator is ineffective if worn incorrectly. Proper fit, use, and care are fundamental to your safety. Whether you're using a disposable N95 for sanding or a reusable elastomeric respirator for painting, getting the basics right makes all the difference.

The Role of Exhalation Valves in PPE Masks

Some respirators have exhalation valves to make breathing out easier and reduce heat buildup, increasing comfort during demanding work. However, most valves allow unfiltered air to escape when you exhale. This means the respirator protects you but does not provide source control to protect others.

Because of this, N95 respirators with exhalation valves should not be used when sterile conditions are required or during infectious disease outbreaks. If your goal is to protect both yourself and others, choose a respirator without a valve or one with a filtered exhalation valve.

Proper Use, Care, and Disposal of Your PPE Masks

Following these crucial practices will ensure you get the most from your PPE Masks.

Donning, Doffing, and Seal Checks: Always put on and take off your mask according to the manufacturer's instructions. For tight-fitting respirators, you must perform a user seal check every time. To do this, cover the filter and inhale sharply; the respirator should pull slightly against your face with no air leaks. If you feel a leak, readjust and try again. Without a proper seal, you are not protected.

Fit Testing: In occupational settings, annual fit testing is required to ensure your specific respirator model creates a complete seal. Testing should also be repeated after significant changes to your facial structure (e.g., weight change, dental work).

Storage: Keep masks and respirators in a clean, dry place away from contaminants, sunlight, and extreme temperatures. Clean and disinfect reusable respirators after each use per manufacturer guidelines.

Reusability and Replacement: Disposable masks like N95s are for single or limited use. Discard them if they become damaged, soiled, or hard to breathe through. For reusable respirators, replace cartridges and filters based on your exposure levels and the manufacturer's schedule.

Safe Disposal: Used masks can harbour contaminants. Place them in a plastic bag before putting them in the trash, and always wash your hands thoroughly after handling. For more details on respirator use, refer to the Respirator Types and Use page.

Frequently Asked Questions about PPE Masks

What does NIOSH approval mean and why is it important?

NIOSH approval signifies that a respirator has passed rigorous testing by the U.S. National Institute for Occupational Safety and Health. These standards are a global benchmark for quality. Approval guarantees the respirator meets specific performance criteria for filtration efficiency, breathing resistance, and strap integrity. It also confirms the manufacturer has a solid quality control program. For professional workshops, using NIOSH-approved respirators is often a requirement under health and safety regulations, like OSHA's 29 CFR 1910.134, ensuring the PPE Masks you use will perform as expected.

How does fit impact a mask's effectiveness?

Fit is as crucial as filtration. A respirator must form a tight facial seal to force all inhaled air through the filter. If gaps exist, contaminated air bypasses the filter, rendering it ineffective. A poorly fitted respirator with a 95% filter can offer less protection than a well-fitted one with an 80% filter.

Facial hair is the most common cause of a poor seal; even stubble can create leaks. This is why fit testing is mandatory in professional settings to verify that a specific respirator model, style, and size seals properly to your face. Without a successful fit test, you cannot be sure you are protected.

What is the difference between protecting the wearer and protecting others (source control)?

This distinction is key to choosing the right mask. Protecting the wearer (inward protection) is the primary job of a respirator. It uses a tight seal and efficient filter media to clean the air you breathe in. This is true personal protective equipment.

Protecting others (source control or outward protection) is the main purpose of masks like surgical or cloth types. They are loose-fitting and designed to capture the droplets you exhale, preventing them from spreading. They offer minimal inward protection for the wearer.

An exhalation valve is a perfect example of this difference. A respirator with an unfiltered valve protects the wearer but allows their unfiltered breath to escape, offering no source control. If you need to protect both yourself and others, choose a non-valved respirator.

Selecting the Right Protection for the Job

Choosing the right PPE Masks is straightforward once you understand the key differences between respirators and general use masks. This knowledge allows you to make confident decisions to protect your health in any environment, from an automotive workshop in Dandenong South to an industrial facility in Victoria.

When you're dealing with fine dust, chemical fumes, or hazardous vapours from automotive paints, a certified respirator is non-negotiable. Disposable N95s are excellent for filtering particles, while reusable elastomeric respirators with the correct cartridges offer superior protection against both particles and chemical vapours, which is essential when working with 2K paints or isocyanates. General use face coverings like surgical and cloth masks are for everyday source control and are not suitable for workshop hazards.

At Eastern Auto Paints, we have over 34 years of experience helping customers steer these respiratory challenges. We know what you're up against, from panel prep dust to the complex chemicals in modern coatings. Our expert staff are here to guide you to the right PPE Masks and respirators for your specific work environment, because your safety is not something to compromise on.

Ready to get the protection you need? Explore our full range of PPE Masks designed for demanding professional work. If you need custom advice, we're here to help. Contact us for expert advice or visit us at our Bayswater or Dandenong South locations. Your health matters, and we're here to make sure you're properly protected.